Premier Aluminum Llc Can Be Fun For Anyone

Table of ContentsThe 8-Minute Rule for Premier Aluminum LlcAbout Premier Aluminum LlcEverything about Premier Aluminum LlcThe Main Principles Of Premier Aluminum Llc

(https://old.bitchute.com/channel/CkdxmIkh56Dq/)Typically, a purchaser's key duty was to locate competent and responsive suppliers. In some instances, purchasers assumed that any type of supplier prepared to contractually meet the acquisition requirement was qualified. Using low expense and unqualified vendors can cause quality problems, and threw away time and money in the lengthy run. To help you with the process, right here are some points to take into consideration when choosing the appropriate steel casting vendor.

A business that only utilizes the investment casting process will try to market you on why that process is best for your application (Aluminum Foundry). Yet what happens if making use of the sand spreading process is best for you and your demands? Instead, look for a vendor that supplies a range of casting procedures so the very best choice for YOU is chosen

If working with a single resource for every one of your casting requires is essential to you, the supplier requires to be varied in its capacities. When integrated with various other incorporated capabilities, this can help streamline and press the supply base. When selecting the appropriate casting provider, cautious consideration should be provided to high quality, solution, and rate.

What Does Premier Aluminum Llc Do?

Buyers significantly choose casting providers who have machining capacities. If the casting provider finds a concern throughout machining, the issue is settled faster with no dispute over whose fault it is.

What do you require from your spreading vendor? Are you looking for somebody to simply provide a steel part to your front door or do you require more?

Some shops are minimal or specialized. Make sure the vendor can meet all your material or alloy requirements to eliminate the need for multiple providers.

Some Ideas on Premier Aluminum Llc You Should Know

Research study the distributor's web site. Talk to a sales rep or service associate.

Light weight aluminum is likewise light-weight and has great deterioration resistance, making it suitable for applications where weight and longevity are essential aspects. Additionally, light weight aluminum spreading is an economical method of manufacturing, as it calls for much less energy and resources than other techniques. Iron spreading, on the various other hand, entails putting liquified iron into a mold and mildew to produce a preferred form.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Iron spreading is additionally able to withstand heats, making it suitable for use in content applications such as engine parts and commercial equipment. Iron spreading can be much more costly than aluminum spreading due to the higher expense of raw materials and the power required to thaw the iron. When determining in between light weight aluminum casting and iron casting, it is very important to take into consideration the particular requirements of the application.

If stamina and durability are more crucial, iron casting might be the far better alternative. Other aspects to think about consist of expense, production quantity, and preparation. To conclude, both light weight aluminum casting and iron casting have their very own one-of-a-kind advantages and disadvantages. By meticulously considering the details needs of the application, producers can pick the very best process for their product.ZheJiang Dongrun Spreading Market Carbon Monoxide,. Ltd was built in 1995, We have remained in the spreading market for greater than 25 years. Pass away spreading is the name provided to the

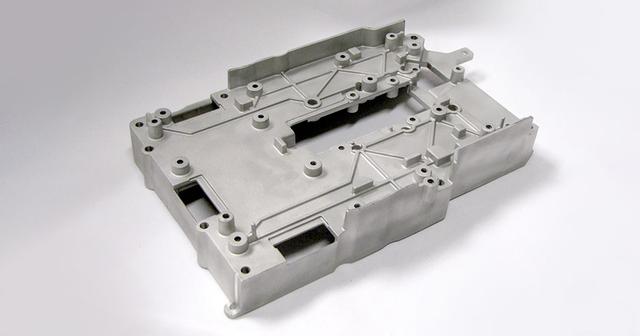

process of producing complex metal elements via use molds of the part, likewise understood as dies. The process uses non-ferrous steels which do not have iron, such as light weight aluminum, zinc and magnesium, because of the desirable residential or commercial properties of the steels such as low weight, higher conductivity, non-magnetic conductivity and resistance to deterioration. Pass away spreading manufacturing is quick, making high manufacturing levels of elements easy.

It produces even more elements than any various other process, with a high degree of precision and repeatability. To get more information regarding die spreading and pass away casting materials used in the process, kept reading. There are 3 sub-processes that drop under the classification of die casting: gravity pass away casting (or irreversible mold spreading), low-pressure die spreading and high-pressure die casting. The pure steel, also called ingot, is contributed to the heating system and maintained at the molten temperature of the metal, which is then transferredto the shot chamber and injected into the die. The stress is then maintained as the steel strengthens. When the metal strengthens, the cooling process begins. The thicker the wall of the component, the longer the cooling time as a result of the amount of interior metalthat additionally needs to cool. After the element is totally cooled, the die cuts in half open and an ejection system presses the component out. Complying with the ejection, the die is closed for the following injection cycle. The flash is the additional product that is cast throughout the procedure. This have to be cut off making use of a trim device to

leave just the primary component. Deburring removes the smaller sized items, called burrs, after the trimming process. The component is polished, or burnished, to provide it a smooth finish. This confirmed to be an imprecise test, due to the fact that the tester might reduce right into an item and miss out on an area with porosity. Today, top producers make use of x-ray testing to see the whole interior of parts without cutting into them. This permits them to more properly approve or turn down parts. To reach the ended up item, there are 3 primary alloys made use of as die casting material to select from: zinc, aluminum and magnesium. Zinc is just one of one of the most pre-owned alloys for die spreading as a result of its reduced cost of basic materials.